Innovative grippers for

innovative industries

© SCHUNK SE & Co. KG, 2021

Adhesive grippers for the handling of demanding components

Our grippers are particularly suitable for gripping and holding clean workpieces in the e-mobility, optics, life science, electronics and packaging industries. Even sensitive battery and fuel cell components can be handled safely.

New Automation Opportunities

in challenging environments such as clean rooms and vacuum production

CO2 Footprint Reduction

thanks to handling without compressed air or vacuum infrastructure

Handling Fragile Objects or Surfaces

from cm² up to m²

Reduction of noise emission

improvement of production conditions, occupational safety

Industries and applications

E-Mobility and Automotive

Increasing the throughput in fuel cell and battery production by creating new possibilities in handling sensitive components.

Life Science and Medical Technology

Creating new gripping opportunities in automation processes with strict requirements such as cleanroom applications by fully eliminating vacuum pumps and air supply.

Electronic

Handle various geometries and surface finishes using a universal gripper. Parts with holes and uneven surfaces can be gripped without complicated pre-handling adjustments.

Semiconductor Technology

Increase cycle speed and process flexibility in the handling of fragile components during costly and complex automation operations inside vacuum environments.

Packaging Industry

Effortless and gentle handling of irregular shapes without using complex infrastructure.

Optics

Reduce the post-processing steps thanks to residue-free handling.

From robots to complex production plants -

any automation unit can be equipped with adhesive grippers.

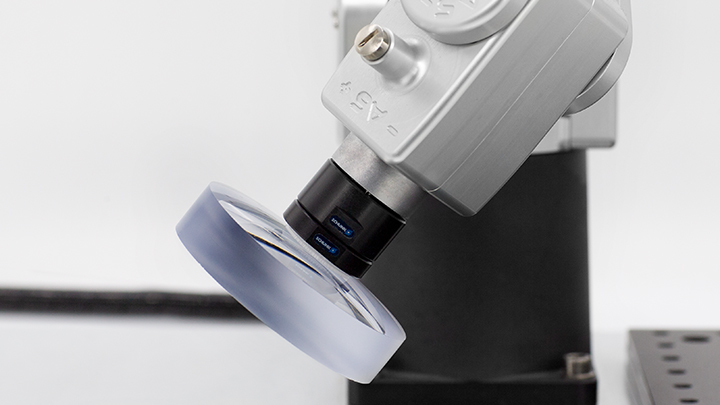

Standard gripper ADHESO

We work with the industry leader for gripping and clamping technology, Schunk GmbH & Co. KG to combine our gripping technology with standardized components. The result is ADHESO, the compact adhesive gripper with bayonet lock.

• Honored with the German Innovation Award

Customized gripping solution

As an interdisciplinary team of material experts, development engineers and designers, we develop the gripping solution to meet your requirements.

• Adaptation of the gripping technology to your components and processes

• IIntegration of the technology into your existing system

We know that our customers’ processes are demanding and individual, which is why we offer various options to customize and integrate our technology. Arrange a consultation.

-

Feasibility study

We perform extensive handling tests with your components and recommend the appropriate gripper.

-

Standard gripper

The ADHESO adhesive gripper from SCHUNK is equipped with our technology and is available as a standard component.

-

Special gripper

You receive a special gripper that is tailor-made for your object and your process.

-

Development project

We develop the complete gripping process for you - also for high temperature, clean room or UV applications.

We know that our customers’ processes are demanding and individual, which is why we offer various options to customize and integrate our technology. Arrange a consultation.

Feasibility study

We perform extensive handling tests with your components and recommend the appropriate gripper.

Standard gripper

Our standard grippers Arigrip and Beagrip are suitable for many applications and can be combined with other components.

Special gripper

You receive a special gripper that is tailor-made for your object and your process.

Development project

We develop the complete gripping process for you - also for high temperature, clean room or UV applications.

Ready to get started?

Discuss your process requirements with one of our experts.

We will be happy to answer your questions about integrating our gripping solution into your next project.

Yolanda Stabel

Sales Engineer

Ana Karina Haller

Sales Engineer